A contract research organization whose focus is translating new technologies that support better health outcomes for humans, animals, and the environment identified pressurization/monitoring issues with their Animal Biosafety Level 3 (ABSL3) and Biosafety Level 3 (BSL3) lab containment spaces. The issues were severe enough that the facility shut down three large ABSL3/BSL3 spaces and made a commitment to improving the performance and reliability prior to recommissioning the labs for use.

The engineer, mechanical contractor and the owner identified the current lab HVAC operating conditions. Based on that survey and lab protocol, the engineer designed a new lab HVAC layout and operating conditions for precision air valves to provide proper air pressure relationships and air change rates. The decision was made to replace all precision air valves in two of the three lab spaces, improve monitoring/controls throughout the lab, and rebalance the air handling equipment. The mechanical contractor engaged the manufacturer’s representative Jorban-Riscoe looking for a solution to the existing operation of the ABSL3 and BSL3 lab spaces.

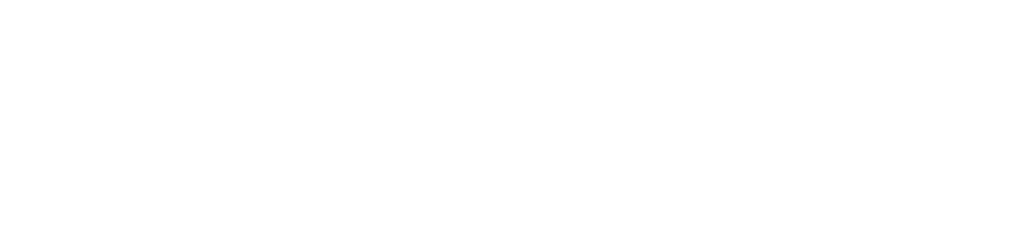

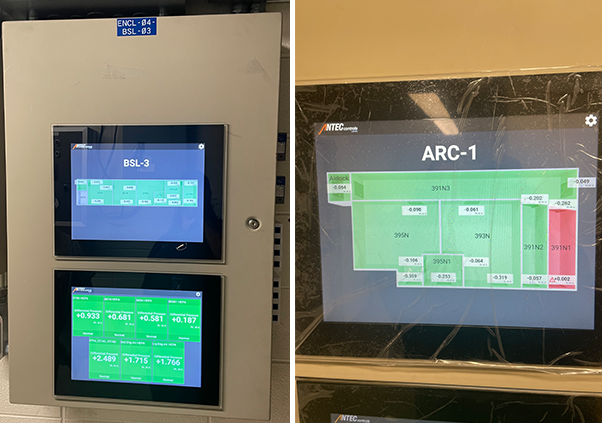

In collaboration with the design team, Jorban-Riscoe determined that Antec Controls was the manufacturer to solve the issues. Fast-acting VFX (high accuracy) air valves were used for the supply and general exhaust of each room. Antec Controls’ VFX air valve was chosen for this project due to its low-pressure requirements which fit the existing system. Multi-stage electric coils with custom sequencing and thermostats were added to each space to provide precision temperature control. With the facility also looking to upgrade their pressure monitoring, a 15-inch custom touchscreen display was added to each critical space, displaying room pressure relationships on a customized floor plan display. This allowed lab techs to quickly view and determine the pressure relationships in adjoining spaces, keeping them safe when entering. Due to the aggressive schedule, all equipment was ordered with a two-week quick build which was completed by Antec Controls’ incredible manufacturing team. During the install process, it was determined that two existing fume hood valves were damaged and needed to be replaced. Antec Controls manufactured and shipped out two new valves in three days to keep the project on schedule.

The air supply and exhaust systems are now operating at lower speeds than they had historically, and they have tremendously better temperature control in each lab. The number of air changes per hour has been reduced in the lab which has resulted in energy savings and overall, a better research environment for the technicians to work in. The custom touchscreen displays outside of the laboratories are intuitive and the technical staff enjoy how simple it is to ensure the labs are safe to enter.